Hardwood Repair Kit 50ml size with 3M Scotch-Weld DP100 3-5 Min Fast Set Hardwood Epoxy Adhesive

Product details

- Type Hardwood Epoxy Repair Kits

- Vendor Maven

- SKU 3M_WOOD_DP100_050ML_GUN_KIT

- Barcode DP100 Hardwood

Harwood Epoxy Repair Kit, with 3M Scotch-Weld DP100 Epoxy (aka Hardwood Epoxy). This hardwood repair kit allows fast repair of loose hardwood pieces by mixing and dispensing precise amounts of hardwood epoxy for fast and efficient repairs. solid footing is a fast drill and fill. No stirring, pouring, or related messes.

Includes:

- 1 each of 50ml (1.7 fl. oz.) 3M ScotchWeld DP100 Epoxy Cartridge (aka Hardwood Epoxy)

- 2 each Mixing Nozzles

- 2 each 1-inch long 14-gauge Green Needle Tips

Applications:

- Fill pre-finished floor hollows

- Fill knot holes in rustic flooring and dries translucent to let natural beauty show through

- Repair split boards

- Apply or replace moldings

- Many other types of general repair

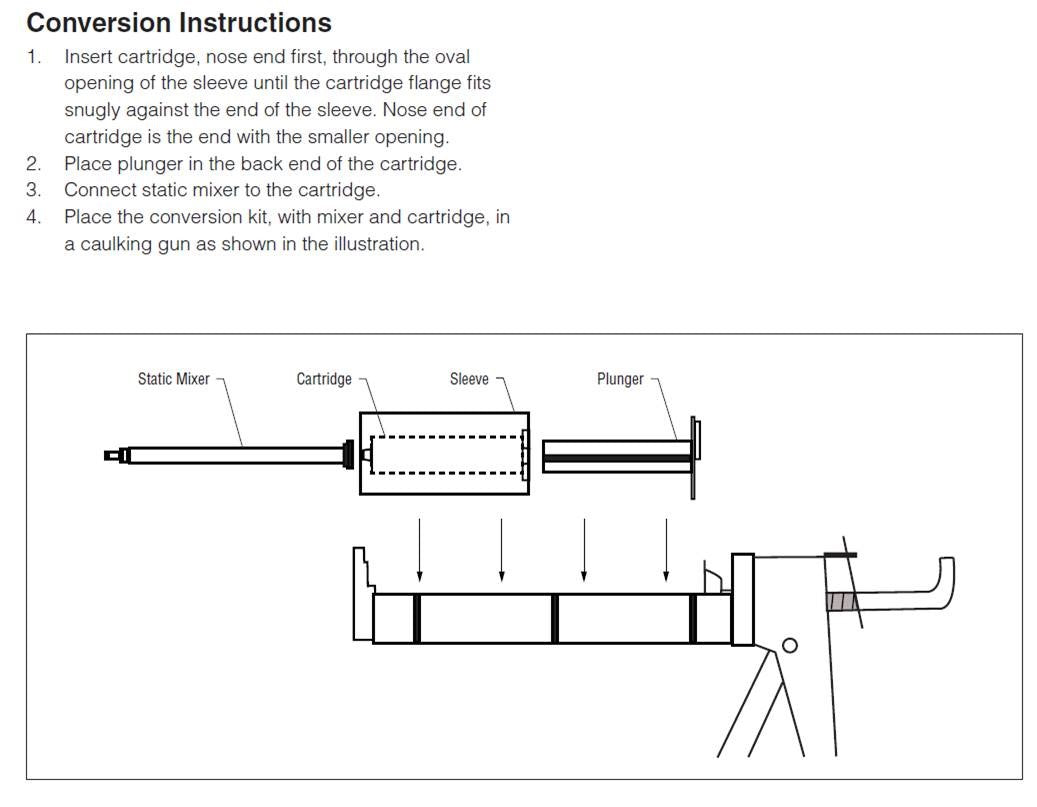

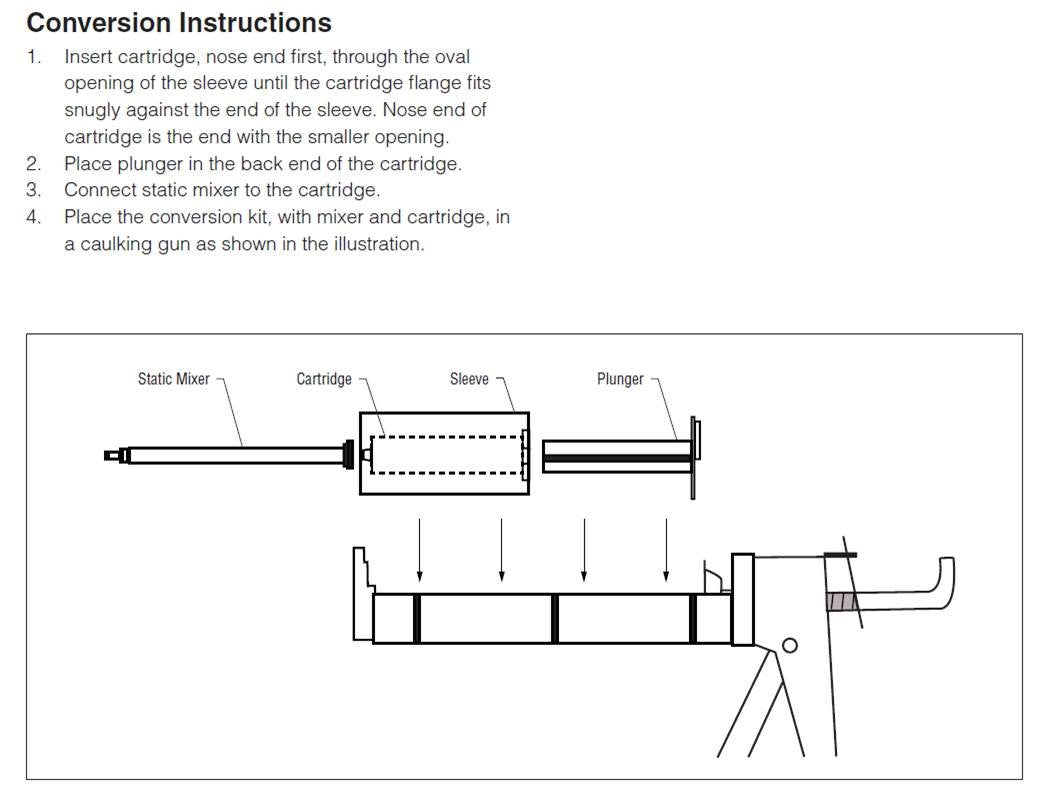

Instruction Sheet: Atlas Professional Hardwood Repair Kit Instructions

The 3M ScotchWeld DP-100 formula (aka Hardwood Epoxy) is the extremely popular 3-5 Minute Extra-Fast Setting Clear Epoxy Adhesive. It is a fast set/cure multipurpose, two-component, room temperature clear Epoxy adhesive of good strength and toughness. It is also an excellent bonder for Steel (ferrous and stainless), Aluminum, and many types of Plastics.

Please Note: These cartridges are designed to work best with a 50ml cartridge Dispenser. It is strongly advise you use a 50ml Dispenser for this cartridge. This 3M cartridge will fit into any standard ‘Square-Back’ Dispenser. If you do not have this, please check out the Kit that includes a dispenser, or search for the “MixPac 50ml Dispenser”.

- Work Time: 3-5 minutes set

- Handling Strength: 15-20 minutes

- Full Cure Strength: 24 hours

- Color: Clear

- Viscosity: Thin Syrup (8,000 to 17,000 cps)

Typical Uncured Physical Properties:

The following technical information and data should be considered representative or typical only and should not be used for specification purposes. Viscosity1 Base 8,000-15,000 cps Accelerator 10,000-17,000 cps Color Clear/Lt. Amber Net Weight Base 9.5-9.9 Mix Ratio (B:A) Volume : 1 1 Worklife2 10 g mixed 5 minutes 5 minutes (Gel time3) Typical

Cured Physical Properties Physical:

Color Clear Shore D Hardness 80-85 Time to Handling Strength4 15-20 min. @ 23°C (73°F) Cure Time5 24-48 hours @ 23°C (73°F) Thermal: Wt. loss by Thermal 5% @ 307°C (585°F) Gravimetric Analysis6 Glass Transition Temp7 33°C (91°F) Thermal Conductivity9 0.107 @ 46°C (115°F) Electrical: Dielectric Strength 860 volts/mil 1100 volts/mil (ASTM D 149) Volume Resistivity 3.5 x 1012 ohm-cm 2.2 x 1014 ohm-cm